A professional consulting service is free for all customers. From problem finding, project evaluation, feasibility tests, to after-sales personal technical specialist support…

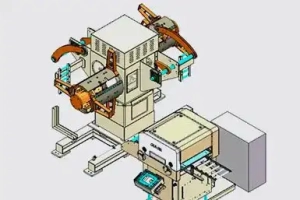

According to your specific application, HE-machine will offer personalized coil handling solutions with stable and reliable performance. Click to find out what can HE do for you, and how …

Our customers will get lifelong services and one-year free after-sales for the coil feeding equipment. Click to find more about the installation service, on-site training, regular …

Our customers will get lifelong services and one-year free after-sales for the coil feeding equipment. Click to find more about the installation service, on-site training, regular security check, and spare parts repair…

For better coil machinery service, HE offer related products in low margins, includes safety barrier fence, safety curtains, lubrication unit, scrap choppers, rubber feet, BDC detecter, and quick die change system…

Gaining competitive advantage requires operations running as stable as possible, and a reliable partner is a key. Whether you’ve been in the industry for decades or just starting, HE-machine is here to help…

For the coil feeding equipment that go LCL shipping, ZheSheng will use plastic films wrap on the equiment, and then fix it into a wooden box.

For the large coil lines that go FCL shipment, ZheSheng will fix each part with ropes on the shipping container and then wrapped them with plastic films.

For standard version decoiler, straightener or feeders, it needs 15-20days for manufacturing. But we usually have machines in stock. Please contact with our sales if you need the coil handling equipment urgently.

For compact coil lines or whole metal stamping lines, it needs 35-70 workdays depends on different specifications.

The possible reason is the main power cable of the hydraulic system has been reversed. If the motor is reversed, the hydraulic station will not work.

Any questions during the decoiler straightener feeder installation, please feel free to contact us at any time.

Yes, our machines come with a 1-year warranty as standard. Also, the warranty time can extend according to specific equipment and customer requirements.

- Check if all the screws parts are in good condition without loose.

- Check if the pneumatic tube is ok without leaking.

- Check if the water filter is dry, if no, please drain water away.

- Make sure the pressure regulator is setting right, we suggest 3 kg/cm2

- Lubricate the transmission gears when needed (ISO VG320 ~ VG370)

- Make sure the extension wiring is ok.

- Check if the feeding rolls are clean, if no, please clean it immediately.

- Check the control panel, make sure the switch, light and monitor are in normal conditions.

- Make sure the solenoid valve is clean.

For more details about operation and maintenance of servo roll feeder machine, please contact us now.

ZheSheng accepts T/T payment and LC at sight.

We believe that we should choose the most suitable machines after understanding our customers’ application and needs. Some machines are multi-functional, but we don’t always recommend our customers go for the most expensive coil equipment. Sometimes, your applications do not require this. We will discuss the detailed coil feed solution with you and direct you to the best equipment.