In the press feeding line, a metal coil will be uncoiled, straightened, and then feed into a stamping press. Consequently, a precision coil feeding line will help you handle various types of coil material in a different situation and improves efficiency.

Applicable Material

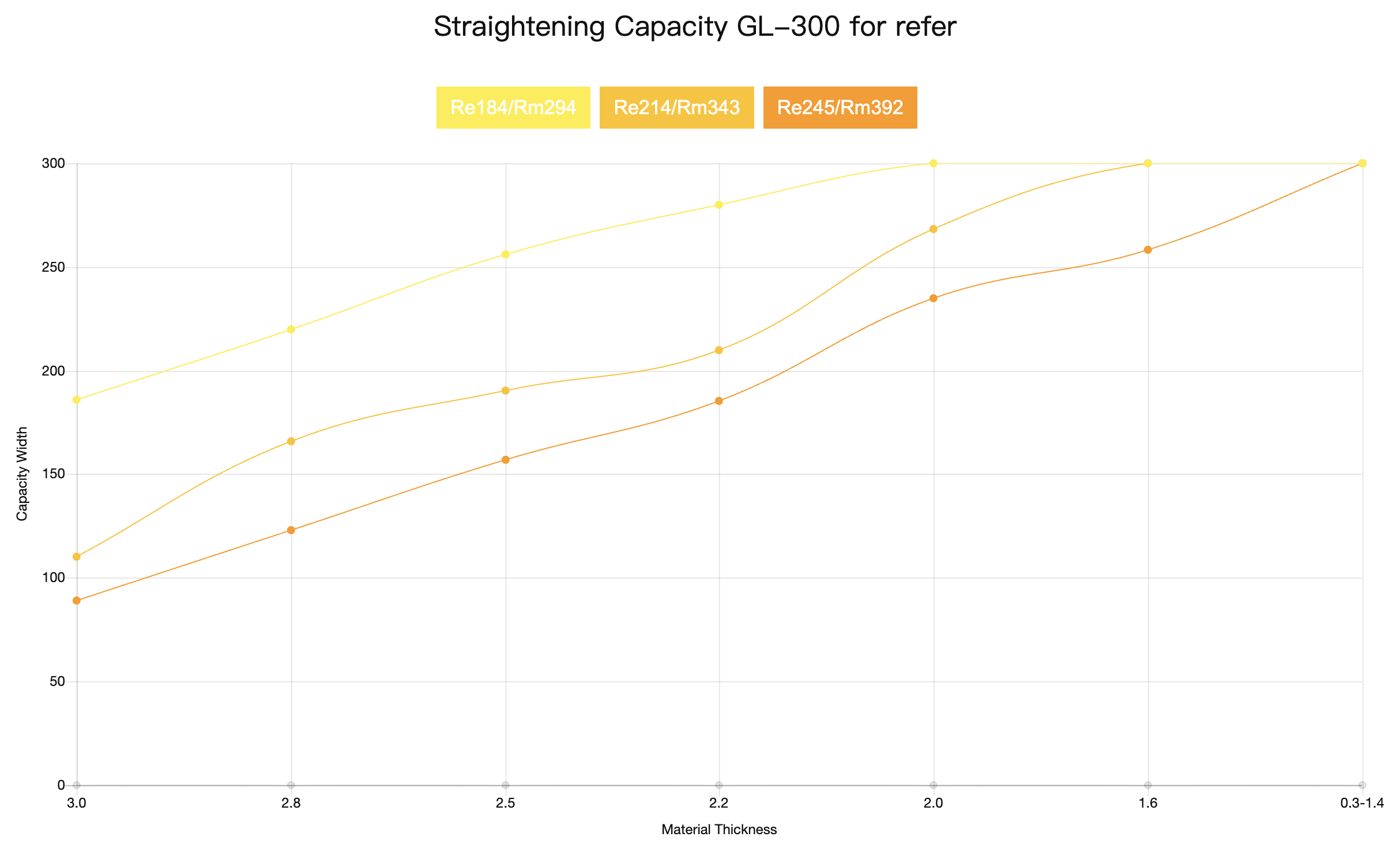

- Material Thickness: 0.2-3.5 mm

- Coil Width: 20-800 mm

Press Feeding Line Structure

- Combined Uncoiler Straightener GL

- Servo Coil Feeder RNC/NCF

- Stamping Press 25-250ton

Features

Space-saving and high synchronization

This line combines the decoiler and straightener parts, which saves the material loop space. Moreover, it achieves the highly synchronize between uncoiling and straightening processes.

Precision straightening performance

With 7pcs high-quality rollers, the combined decider straightener machine is capable of handling a variety of high precision straightening requests. Meanwhile, the 15pcs roller type is capable of handling the higher rigorous straightening requirements. Besides, for some copper or aluminum material, it has an operable straightening part for easy clean and maintenance.

Main Parts Description

1. Combined Uncoiler Straightener

Firstly, there’re passive uncoiler as well as motorized uncoiler, according to different material types. That is to say, passive uncoiler will be suitable for the general stamping process. However, when the thickness is thin, and surface requirements are particularly high, motorized uncoiler parts will be applied. Besides, when the coil is a springy type, a hold-down arm with pneumatic pressure will be suitable for this situation.

Secondly, all the rolls are made by Gcr15 bearing steel, with surface thickening chrome grinding. And the pressure on straightening rolls is the pneumatic type with worm wheel adjustment for precision and smoothly press feeding process.

2. Servo Feeder

Modular design and computer control system makes ZheSheng servo feeder easy to install, intelligent to operation, and with precision feeding, small noise, and easy maintenance. Firstly, the upper roller release system is a pneumatic type. So it helps to reduce feeding error when rollers release in the press feeding process. Secondly, ZheSheng offers Yaskawa or Siemens servo system for customer choice. Therefore, the feeding accuracy is about ± 0.1 m, with max.speed 20m/min.